Unlocking environmental benefits for your company by creating an Environmental Product Declaration (EPD)

Introduction

The global construction sector is responsible for a staggering 39% of energy-related greenhouse gas (GHG) emissions. Of this, 28% can be attributed to operational emissions from buildings´ energy consumption, while the remaining 11% arises from embodied emissions in building materials and the construction process.

In response to this pressing issue, the European Union (EU) has introduced new policies and building designs that emphasise a comprehensive lifecycle approach for considering and managing the sector´s emissions. This approach aims to tackle operational carbon emissions, the carbon embodied in building construction processes and materials.

Why have EPDs matter?

Environmental Product Declaration (EPD) is a vital tool in this endeavour, which offers a reliable, certified, and independently verified assessment of a product’s environmental impact. EPDs have gained significant recognition among industry professionals and policymakers as they are pivotal in addressing embodied carbon within the construction sector. For example, all public procurement bodies in the EU must use EPDs to assess the environmental performance of products. New building regulations that set targets for embodied emissions in buildings are also being implemented in the Netherlands, France, Norway, Finland, and Denmark.

By composing EPDs, companies can gain valuable insights into the environmental performance of their products and make informed decisions to reduce their carbon footprint.

At Civitta, we specialise in assisting companies in the development of EPDs and unlocking the environmental benefits associated with them. Our comprehensive service can guide your company through the entire process, ensuring accurate assessments and helping you maximise the positive impact of your products on the environment. Please visit our website to learn more about the benefits of EPD and how our services can benefit your company.

Decarbonisation of the construction sector: the crucial role of low-carbon materials

Recognising the urgency of climate change, the EU has adopted the European Green Deal, establishing two principal climate goals: a 55% reduction in GHG emissions by 2030 (compared to 1990) and achieving carbon neutrality across the entire union by 2050. Achieving these goals requires decarbonising the construction sector, which accounts for a staggering 39% of the global energy-related GHG emissions. Out of this figure, 28% can be attributed to operational emissions from the buildings´ energy consumption, while the remaining 11% is associated with the construction materials´ production and construction processes — i.e., embodied emissions.

In addition to the overarching climate goals, the European Green Deal mandates that all new buildings must be zero-emission by 20302. That means these buildings must exhibit high energy efficiency, consume minimal energy, and rely solely on renewable energy sources. Furthermore, there is increasing pressure to measure and disclose carbon emissions throughout the entire building lifecycle, encompassing operational and embodied emissions from material production, transportation, construction, demolition, and waste management. It is crucial to prioritise low-carbon materials to minimise embodied emissions and realise the ambition of zero-emission buildings. Structured quantification and transparent disclosure of GHG emissions guide decision-makers in identifying emission reduction needs and required actions. But the rationale extends beyond the political agenda.

Environmental indicators measured

Within recent years, there has been a considerable increase in the market demand for sustainability, which has significant financial implications for businesses, as quantifying and publishing the product´s environmental impact enables to:

- Identify possibilities for increased resource efficiency in production and waste reduction, thus lowering operating costs.

- Promote the manufacturer’s sustainability message and give the client an inside look into the product’s life cycle that may be difficult to gain otherwise.

- Compare the product with similar alternatives from competitors regarding environmental impact. It also showcases areas where your product excels and will leave you better prepared to meet growing market demands for product sustainability.

- Increase the product´s competitiveness in the construction sector because a certified product is a market advantage to the client. EPDs are required in most green procurements and certifications like LEED, BREEAM or DGNB.

At Civitta, we believe that addressing the environmental impact is a driving force for product portfolio development and a key differentiating factor in the competitive landscape. We advise companies to embark on their sustainability journey by quantifying their products´ environmental impact, for example, by creating an EPD.

What is an EPD?

An Environmental Product Declaration (EPD) provides objective, comparable, and verified data about the environmental impacts of products or services throughout their life cycle.

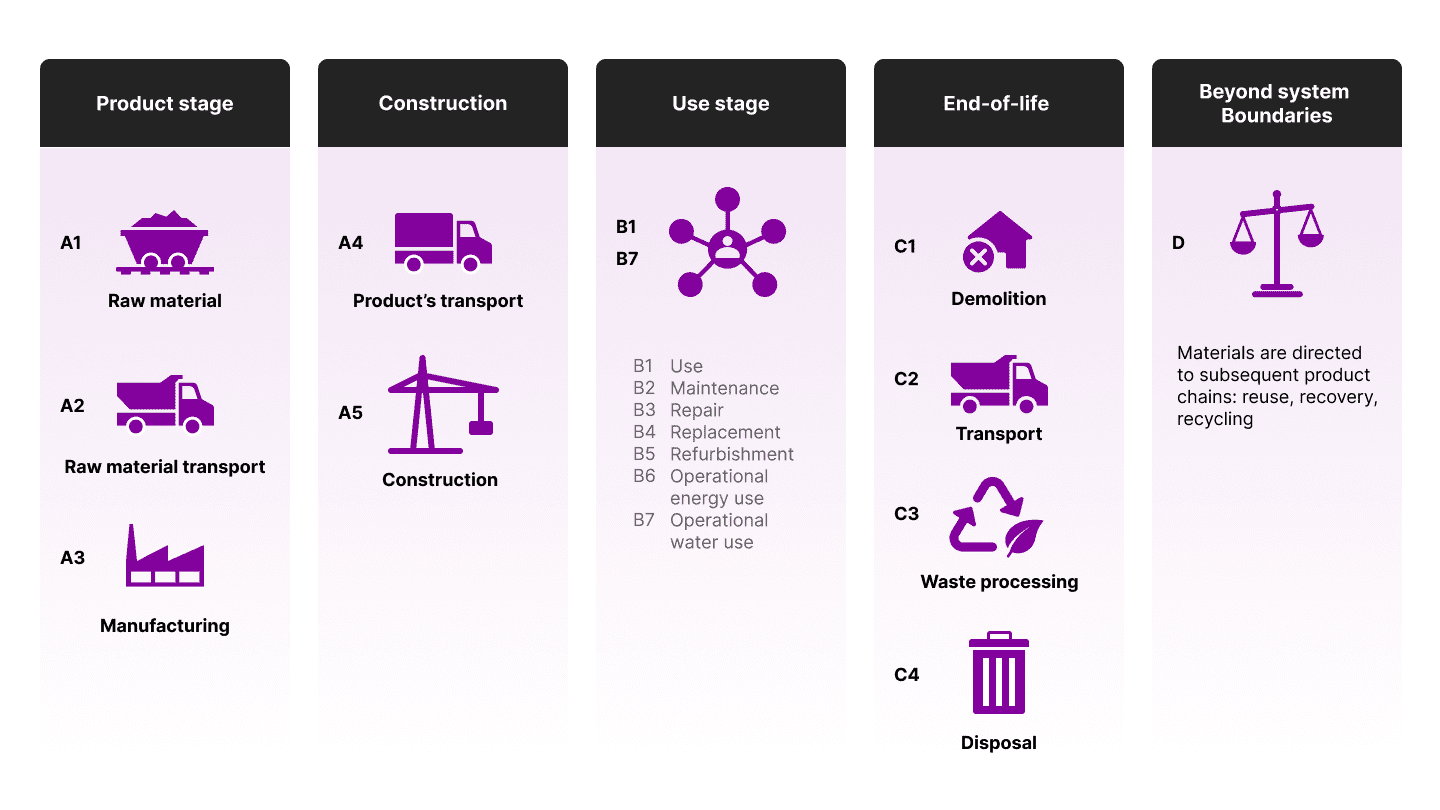

EPD is a transparent and well-established approach to providing essential and verified environmental information about a product. This declaration is based on a comprehensive life cycle assessment (LCA) that evaluates the environmental impact of a product or a product group. EPDs are following the standards EN 158043 and LCA standards ISO 14040 and ISO 14044. The mandatory scope for an EPD is the production stage (A1-A3), end-of-life (C1-C4) and external impacts beyond the system boundaries (D).

Other modules, including the assembly stage (A4-A5) and use stage (B1-B7), can be applied depending on the client’s needs, but they are not mandatory for the EPD. That ensures that EPDs provide information on both cradle-to-gate (A1-A3) and end-of-life phases (module C), as well as external impacts beyond the system boundary (module D).

The assessment process

Furthermore, the standard mandates the reporting of 13 core environmental impact indicators, including:

- Global warming potential (GWP) is related to global warming caused by GHG emissions. This indicator is split into three categories, which differentiate between atmospheric GHG emissions based on their origin: GWP-fossil, GWP-biogenic and GWP-luluc (land use and land use change).

- Ozone depletion potential (ODP) accounts for impacts related to the reduction of the protective ozone layer within the stratosphere caused by emissions of ozone-depleting substances.

- Acidification potential (AP) accounts for impacts related to the potential acidification of soils and water caused by releasing gasses such as nitrogen oxides and sulfur oxides.

- Eutrophication potential (EP) accounts for impacts related to the potential enrichment of the ecosystems with nutritional elements caused by nitrogen or phosphorus-containing compound emissions. This indicator is split into three categories, which differentiate the potential impact on specific ecosystems: freshwater, marine and terrestrial.

- Photochemical Ozone Creation potential (POCP) accounts for impacts related to the creation of photochemical ozone related to the gas emissions.

- Abiotic Depletion potential (ADP) refers to the removal of abiotic resources from the earth or the depletion of non-living natural resources. This indicator is split into two categories: non-fossil (minerals and metals) and fossil fuels, based on the type of depleted resource.

- Water use deprivation potential (WDP) refers to the relative amount of water used based on regionalised water scarcity factors.

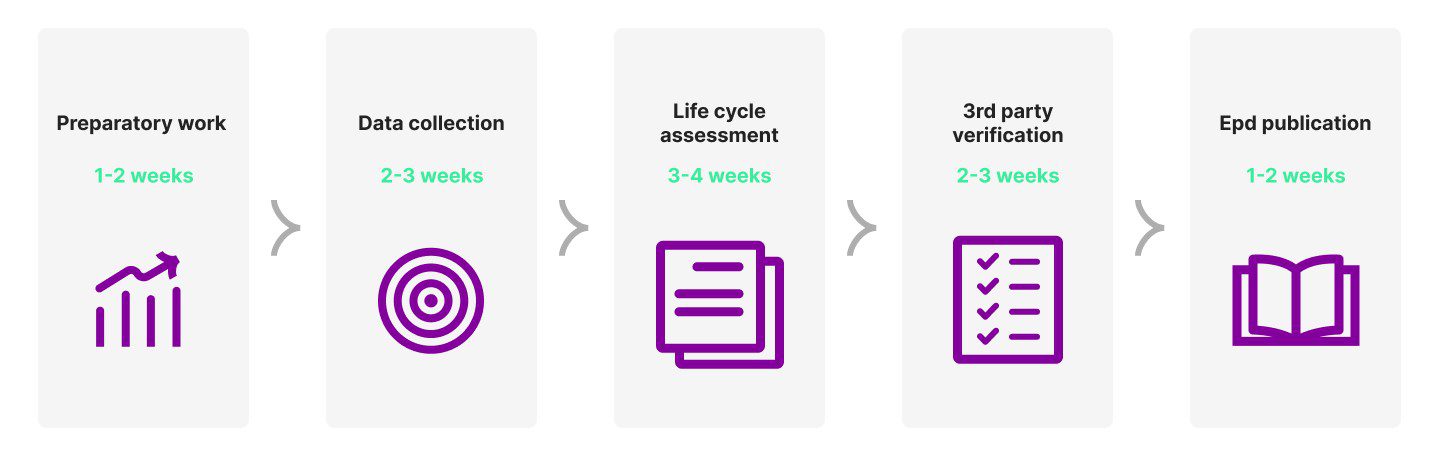

Developing an EPD involves a systematic process encompassing several stages to ensure accurate and reliable environmental information. Let’s explore the key steps involved:

- Preparatory Work: This initial stage involves discussions and decisions regarding the number of products to be included in the EPD, associated variations, included lifecycle stages, etc. Furthermore, it includes selecting an appropriate EPD program operator, an independent agency that administers and supervises the EPD development according to ISO standards. Many countries have their own EPD programs, like Finland – RTS4, Norway – EPD Norge5 and Poland – ITB EPD6. Additionally, international programs like EPD Hub7 or International EPD System8 are available. The selection of a suitable program operator usually depends on geographical area, the working language of the program and the publication cost.

- Data Collection: the second step involves collecting the data about the product’s lifecycle. Depending on the product type and assessment scope, Civitta prepares a data questionnaire to collect the product-specific and company-specific information on the manufacturing (raw materials, production process, energy and fuel use), logistics (transportation modes and distances), product use (electricity consumption), and typical end-of-life scenarios. In this step, Civitta works closely with the company’s representatives to collect all necessary data regarding all life cycle stages of the assessed product.

- Life Cycle Assessment (LCA): Based on the collected data and general data from databases such as Ecoinvent or GaBi on the environmental footprint of materials and processes, we create an LCA model following the reference standard EN 15804+A2 and the product category rules (PCR) specified by the selected EPD program operator. The complete EPD report and a detailed background LCA report, including methodological aspects and study results, are created based on the calculations and findings.

- Third-Party Verification: Once the background LCA report and EPD report are ready, independent third-party verification is conducted to ensure compliance with the standard PCR and the established lifecycle methodology. Feedback and suggestions from the verifier are incorporated to enhance the quality of the EPD. Civitta can not verify the results by itself and needs an external independent verifier. However, we are coordinating the process with the verifier.

- Certification and Registration: after the review process, the EPD documents, along with the verification document, are submitted to the selected program operator for certification. Once certified, the EPD is registered and published on the platform, making it publicly accessible and showing the product’s credibility.

At Civitta, we provide comprehensive support which extends beyond EPD development. We offer assistance in various product assessment methods, including the Product Environmental Footprint (PEF)9 developed by the European Commission and the Product Life Cycle Accounting and Reporting Standard developed by GHG Protocol10. Additionally, we help companies measure their carbon footprint and assess their climate impact at the organisational level, setting up a sustainability strategy and roadmap development, sustainability reporting and compliance.

Our team of sustainability experts is here to guide and support your company in developing an EPD and implementing sustainability initiatives. To explore the possibilities further, feel free to contact us!