Resource efficiency and cleaner production in Uzbekistan industrial zones

Client

United Nations Industrial Development Organization (UNIDO)Client Overview:

The United Nations Industrial Development Organization (UNIDO) promotes sustainable industrial development and green manufacturing, working with governments and industries across approximately 170 countries.

It is a specialized agency of the United Nations (UN) that promotes and leads international efforts on industrial development for poverty reduction, inclusive globalization and environmental sustainability.

The Challenge:

The Uzbekistan Eco-Industrial Parks (EIP) Pilot Initiative (2024–2025), provides technical assistance to two industrial zones – Free Economic Zone (FEZ) Urgut and Small Industrial Zone (SIZ) Mechanic Fergana. The initiative focuses on introducing EIP approaches, with Resource Efficient and Cleaner Production (RECP) as one of its key elements.

The EIP initiative is part of the broader project “Private Sector Development and Economic Policy Advice in Uzbekistan” implemented by the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH in Uzbekistan. The EIP component is carried out by the United Nations Industrial Development Organization (UNIDO).

Manufacturing companies in Uzbekistan’s industrial zones face the dual challenge of staying competitive on cost, productivity and quality while improving their environmental performance. Many lack clear insight into where inefficiencies and financial losses occur in their production processes.

Limited data, weak internal analytics and uncertainty around payback periods further slow progress. UNIDO aimed to help companies turn sustainability goals into practical, economically viable actions on the factory floor.

Zones Explored:

Our Approach:

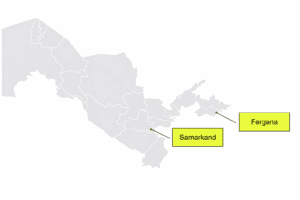

- Civitta supported UNIDO by delivering a comprehensive Resource Efficient and Cleaner Production (RECP) programme across 20 manufacturing companies located in the Samarkand and Fergana industrial zones. The work was designed as a practical, hands-on process that combined technical analysis with a strong business perspective.

- We began with in-depth RECP assessments at each company, analysing production processes, energy and resource flows, waste streams, and emissions. This allowed us to identify where resources were being lost, which inefficiencies had the greatest impact on cost, and which measures could deliver quick wins versus longer term improvements. Each assessment resulted in a tailored action plan, reflecting the specific operational realities and investment capacity of the company.

- For a selected group of 10 companies with high-impact opportunities, Civitta developed detailed feasibility studies focused on priority investment measures. These studies translated technical solutions into financial terms, assessing capital expenditure, operating costs, payback periods, and expected returns. This step was critical in enabling company management to make informed investment decisions with a clear understanding of both risks and benefits.

- To support the transition from assessment to practical implementation, Civitta accompanied companies through structured monitoring and validation of selected measures. Progress on recommended measures was tracked, savings achieved were verified, and assumptions were adjusted based on real operational data. Finally, clear business cases were prepared to communicate results and benefits in a concise and accessible way. All outputs were delivered in English, Russian, and Uzbek, ensuring broad usability within companies and among stakeholders.

- As a result of the project implementation, 6 on-site visits to enterprises were conducted to collect data and validate the assessment results, followed by final meetings with company management to present the findings and discuss next steps. In addition, four advanced training sessions were delivered for 15 experts, focusing on in-depth assessment methodologies, including benchmarking, identification of key performance indicators, material flow analysis, root-cause analysis, and the selection of improvement measures.

Field Insights: Our Experts in the Industrial Zones

Results & Impact:

The project generated measurable economic and environmental results already during its implementation phase, while also creating a strong pipeline for further improvements:

- Implementation of RECP measures – Across the 20 companies, Civitta identified 90 concrete RECP measures covering operational improvements and investment projects. Within the project timeframe, 40 of these measures were implemented, corresponding to a 43% implementation rate.

- Mobilisation of private investment – The identified RECP measures required total planned investments of approximately EUR 3.9 million. Companies have already invested around EUR 825,000 during the project period, moving from analysis to tangible upgrades of equipment and processes.

- Financial performance – Implemented measures have already generated annual financial savings of approximately EUR 350,000. These savings come from reduced energy consumption, lower material losses, and improved operational efficiency, directly strengthening the companies’ cost competitiveness.

- Energy and climate impact – As a result of implemented measures, companies achieved around 3,900 MWh of energy savings per year and reduced greenhouse gas emissions by approximately 2.5 million kg of CO₂ equivalent annually. These results represent around one quarter to one third of the total planned impact, indicating significant additional potential as further measures are rolled out.

Beyond the numbers, the project helped companies build internal understanding of resource efficiency as a strategic business issue, rather than a compliance exercise, creating a foundation for sustained improvements beyond the project lifecycle.

The project was part of the “Eco Expo Central Asia 2025”, event in the field of ecology and green technologies. Check out the full event and interview of our Associate Partner Saidkamolkhon Burkhanov, here:

See more

Key Takeaways:

This project confirms that structured RECP interventions at the enterprise level can serve as an effective entry point for wider industrial transformation. The implementation across individual manufacturing companies generated validated data on resource efficiency gains, investment needs, and achievable economic returns, providing a credible evidence base for decision makers.

Beyond company-level benefits, the results show strong potential for park-wide RECP measures, where shared infrastructure, resource flows, and coordinated investment can amplify impact. This work lays the groundwork for next-phase interventions, including industrial symbiosis and blended finance mechanisms, to support larger-scale transitions toward low-carbon, resource-efficient industrial development.